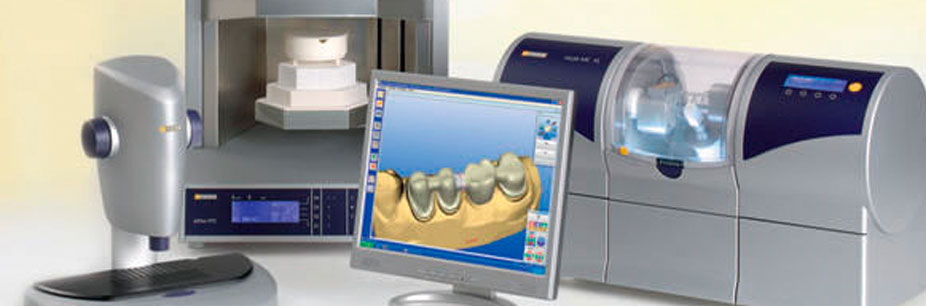

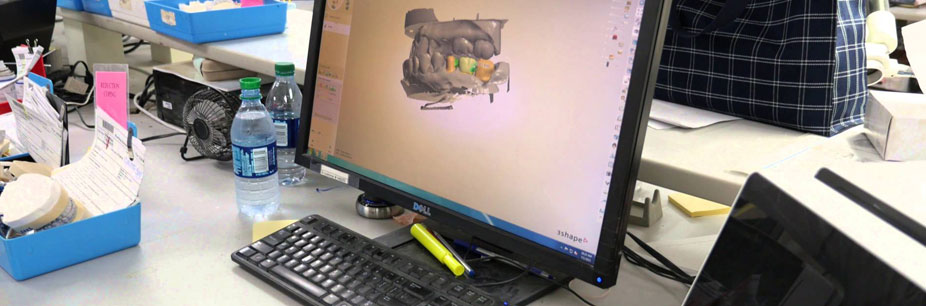

CAD CAM

CAD/CAM stands for Computer-Aided Design/Computer -Aided Manufacturing. It is a technological breakthrough that has left far behind the old methods of dental restorations with metal crowns and bridges.This computer program first goes into effect by taking 3-D images of the patient's teeth and gums. These images of the patient's teeth and gums.

Increase Programming Potential:. By adding CAD-CAM software to your CNC toolkit, you can open up possibilities for your business that may not have been there before. An example of this is gaining the ability to take on harder, more complex 3 Axis machining jobs.

Improved Control Over Job: Modern CAD-CAM functionality includes a CAM Tree Manager that allows you to track the job from beginning to end. You have full control over post processing, stock, work coordinates, material and tooling as well as access to machining operations that determine how the part will be machined as well as the output of the NC Program.

Eliminate Costly Mistakes & Waste: CAD-CAM software provides powerful simulation features. Simulation allows you to visually inspect the machining process, catch costly tool gouges and collisions before they reach the CNC machine. This alone makes adding a CAD-CAM product to the shop a good decision.

Turn Art Into CNC Programs & Finished Parts Easily: Artistic CAD-CAM technology has evolved to support a wide range of custom applications. Two of these specialized industries would be the custom woodworking and jewelry making industry. These types applications require the ability to turn a picture into a 3D relief model that can be machined in a variety of ways. This also includes the ability to turn a picture into 2D profiles that can be used for engraving, pocket milling and profile milling..